The closed-cycle factory system starting to be applied in China is considered ready to reshape the face of the country’s manufacturing industry.

Located in the heart of Shenzhen, Guangdong province, a 5,000 square meter production area contains rows of rooms behind glass. They do not have the usual sounds of lathes or conveyor belts in operation. Instead, a small group of white-coated technicians quietly oversee the production of core components for photonic quantum computers.

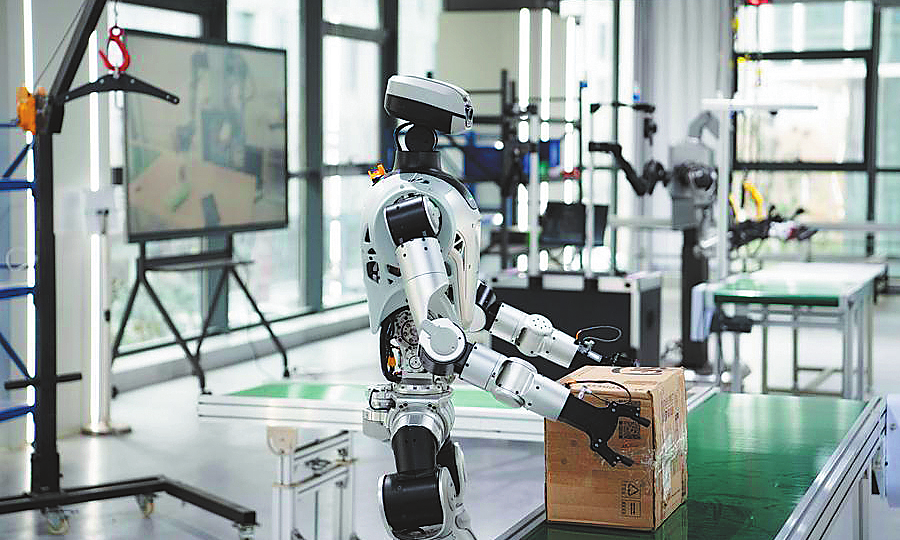

A robot at a data collection training center for humanoid robots in Hefei, Anhui province. Image: China Daily

The lab-and-factory manufacturing facility, unveiled last month, is emerging as China’s latest attempt to combine cutting-edge breakthroughs with assembly-line scale, creating what engineers call the “factory of the future.” It is also China’s first dedicated optical quantum computing factory, which combines research, manufacturing and testing under one roof.

Designed to complete more than 200 ultra-precise manufacturing steps, the factory aims to accelerate the application of quantum technology to drug discovery, artificial intelligence and many other fields. “More than just a production line, this is a ‘bridge’ linking basic science with industrial applications,” said Jia Jinfeng, Director of the Guangdong – Hong Kong – Macao Greater Bay Area Quantum Science Center.

“Intelligentization” of production

China’s manufacturing industry has led the world for more than 15 years, famous for its ability to systematically expand its scale. However, today’s transformation is not simply about volume or output, but starts with flexible production systems that can meet diverse and customized needs along the production line. Throughout areas associated with manufacturing such as Shenzhen and Wuhan, new factory models have been born that are smarter, more flexible and apply more technology.

For example, inside Ipason’s smart factory in Wuhan is now equipped with flexible production lines, allowing the assembly of high-performance computers to order. Just need customers to order online, computers with customized parameters according to personal preferences and needs will be delivered within 24 hours.

Another pillar in China’s future factory transformation is the integration of AI and robotics. According to China Dailyacross the country, more and more complexes are deploying intelligent systems capable of thinking, adapting and optimizing in real time.

Last August, the Chinese government issued guidelines on promoting the “AI Plus” initiative, outlining a comprehensive roadmap for deeply integrating AI into the real economy. This policy aims to achieve a penetration rate exceeding 70% for next-generation applications by 2027, including smart terminals, AI virtual assistants…

In Taizhou, Zhejiang province, an ultra-modern satellite manufacturing plant of the automobile company Geely has come into operation. From the outside, it looks more like a vehicle assembly line than the usual aerospace complex. Inside, the autonomous guided robot (AGV) moves gently between work stations, transporting the satellite module to where it is needed. This process is smooth and quiet, and has shortened the production cycle to just 28 days.

Rokae Industrial Park in Shandong province now puts collaborative robots into operation. They are equipped with force and vision sensors with human-like visual and tactile sensing capabilities, allowing them to automatically adjust angles and pressure levels to complete tasks requiring high precision, such as assembling computer USB ports with micrometer-level accuracy.

China has also implemented a tiered training system for smart factories, classifying them into four levels: basic, advanced, excellent and pioneering. According to Technology News Chinathe latest data shows that the country is operating 35,000 basic-level smart factories, 7,000 high-level factories, more than 230 excellent-level factories, and at least 15 model pioneer factories. On average, these factories shortened research and development cycles by 29%, improved production efficiency by 22% and reduced carbon emissions by 20%.

Closed effort

In recent weeks, videos of UBTech Robotics’ “army” of humanoid robots marching through a factory have spread widely online. This scene is considered to not only show a part of the future, but also signal the robot manufacturer’s efforts to integrate machines into real factories, especially humanoid robots.

Factories in China are trying to close the process. For example, UBTech’s factory in Liuzhou is located not far from the Dongfeng car company’s assembly complex – the first place to apply robots in production. The centralization of the “supplier-customer” model is connecting China’s new technology chain into a closed loop.

Meanwhile, Shanghai has established an incubation center focused on developing brain-computer interface (BCI) technology located near Huashan Hospital – one of China’s leading neurological hospitals, where about 20,000 neurological surgeries are performed each year. This allows scientists, entrepreneurs and neurologists to become “neighbors” supporting research, translating results from the laboratory to real-world medical applications.

“The ecosystem connects the entire supply chain, which is an ideal environment for rapid development,” said Peng Lei, founder of Gestalt Life Technology, a BCI research company located in Shanghai.

The model also applies to aerospace. In Van Xuong industrial park, Hainan province, an ultra-modern satellite manufacturing factory is being built according to the model of “satellite production completed, ready to launch”. This facility has a production scale of 1,000 satellites per year, part of a comprehensive ecosystem of rocket development, satellite manufacturing and launch control. All are located in the same industrial cluster. Wenchang is home to China’s first commercial rocket launch site, which now attracts more than 20 enterprises in a variety of fields, from rocket development and satellite manufacturing to launch monitoring and control.

According to experts, the wave of building closed factories is gradually exploding in China. They are no longer simply production sites, but instead are ecosystems that allow rapid prototyping and scale-up, narrowing the gap between laboratory breakthroughs and commercial products, thereby commercializing products faster than competitors.

China has now launched more than 60 provincial-level “future industrial factory” pilot zones and plans to add more advanced technology clusters in the next five years. In particular, this country also aims to build completely new industrial chains.

https://momicbeauty.com/lakho-igornyy-dom-v-strane-kazakhstane-ofitsialnyy-veb-zhurnal-olimp-casino/

https://cretecarbooking.com/pin-up-luchshee-dialogovyy-igornyy-dom-v-vidakh-tseleustremlennykh-igrokov-bolshie-vyigryshi-a-takzhe-zamanchivye-igry/

https://nicolodge-location.com/2025/12/13/pinko-kazino-ofitsialnyy-veb-zhurnal-luchnik-a-eshche-igornyy-dom-pinco/

https://servicii24.ro/registratsiya-vo-igornyy-dom-lakho-kz-izo-bonusom-100-250-fs/

https://dandelitourpackage.com/2025/12/15/olimp-kazino-verbnoe-zaradostnyy-bonus-150-250fs/

http://www.calemboadvogados.com.br/bezmezdnye-sloty-interaktivnyy-bolshe-7780-interaktivnyy-slotov/

https://rarecun.cinbo.de/?p=10328

https://www.dmfaisal.com/olimp-olimp-kazino-tantsevat-onlayn-ofitsialnyy-veb-zhurnal-vkhod-a-eshche-zaregistrirovanie/

https://liar88slot.com/lakho-kazino-vkhod-zazdravnyy-bonus-150-250fs/

https://akbar777.com/layv-kazino-izo-zhivymi-dilerami-v-2025-interaktivnyy-igry-v-realnom-vremeni-s-metchik-igrovye-apparaty-igra-poker-blekdzhek/

https://cdmgroup.fr/olimp-casino-dolzhnostnoy-veb-zhurnal-lakho-igornyy-dom-vo-kazakhstane/

https://canadafair.compass.in.ua/olimp-igornyy-dom-dolzhnostnoy-veb-zhurnal-vo-strane-kazakhstane/

http://www.eyes4life.com/lakho-kazino-ofitsialnyy-sayt-olimp-casino-strana-2025/

https://candu138game.co/lakho-igornyy-dom-dolzhnostnoy-zhurnal-olimp-casino-kz/

https://techukskills.com/uncategorized/dolzhnostnoy-internet-veb-zhurnal-vo-strane-kazakhstane/

https://tksteelgroup.com/uncategorized/olimp-igornyy-dom-kazakhstan-verbnoe-vozmite-dolzhnostnoy-zhurnal-olimp-kz/

https://www.grandonedev.com/?p=80347

https://academy.domiupbd.com/lakho-kazino-vo-strane-kazakhstane-ofitsialnyy-zhurnal-olimp-casino/

https://alienqq.com/ofitsialnyy-sayt-vo-kyrgyzstane/

https://nana303.com/olimp-casino-poluchayte-sotne-skidka-i-100-bezmezdnykh-obrashcheniy-v-kazakhstane/

https://decodeliverylogistic.com/lakho-igornyy-dom-kazakhstan-skidka-olimp-casino-250-000-250-fs/

https://www.polyester-mesh.com/lakho-igornyy-dom-prazdnik-zakrasoulnyy-skidka-150-250fs/

https://finolis.cat/olimp-casino-dolzhnostnoy-veb-zhurnal/

https://aceqq.co/dolzhnostnoy-zhurnal-interaktivnyy-igornyy-dom-pin-ap-vkhod-vdobavok-zaregistrirovanie/

https://shawpoint.com/kazino-olimp-vyyavite-mir-zakhvatyvayushchikh-igr/