Researchers at the University of Turku investigated how effective UV protection membranes for solar cells can be made from bio-based materials. In most cases, the cells are protected from ultraviolet radiation by coating them with protective films made from PVFD or PET plastic.

Oil -based plastics are looking for more environmentally friendly alternatives in material technology research, one of which is nanocellulose. Nanocellulose is produced by breaking down cellulose into nanoscale strands that can be treated in different ways to achieve UV protection power.

A recent study by the University of Turku, Aalto University and the University of Wageningen found that nanocellulose, colored from the red onion shell, provides a very effective protection against the sun’s ultraviolet radiation.

The film treated with red onion prevented 99.9 percent from UV radiation to 400 nanometers, which means very effective protection. The protective film also outperformed the PET-based protection included in the comparison in its UV protection power, which represented a commercial standard in the study.

“Nanocellulose treated with red onion is a promising material for applications where it is important for protective material to be bio -based,” says a doctoral researcher Rustem nizamov From the University of Turku in the bulletin.

The researchers made four different protective membranes from nanocellulose and compared their protective properties. One of the membranes was treated with a color extracted from the red onion shell, one with lignin and two with iron ions, all of which have naturally been found to have good abilities to absorb UV radiation. The color extracted from the red onion shell proved to be the most effective in comparison.

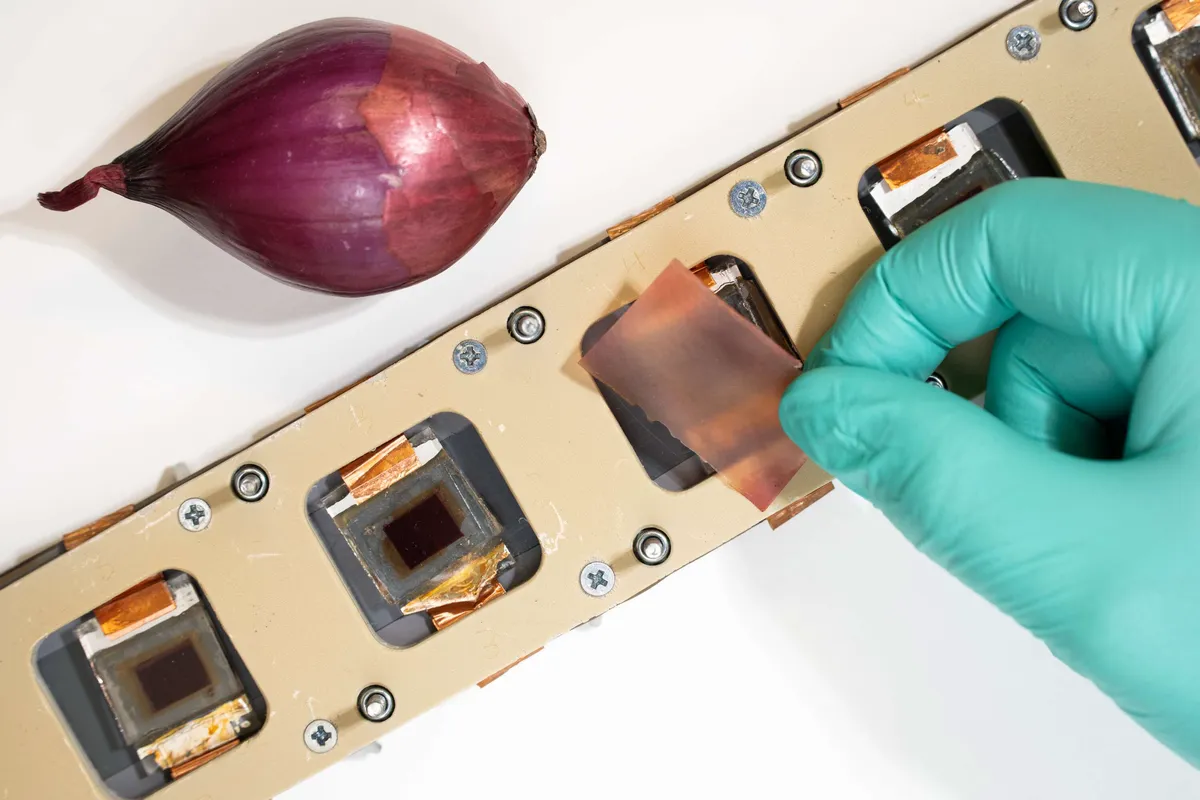

Researcher at work.

Dissertation researcher Rustem Nizamov looks at the color sun cells on the holder in the laboratory.

Photo: Väinö Anttalainen

UV radiation (less than 400 Nm) is harmful to solar cells, while visible light (400-700 Nm) and partly infrared light (especially 700-1200 Nm) are important as this radiation is transformed into electricity.

The challenge in the production of bio-based protective films is often the fact that good UV protection power can impair the permeable light. For example, the dark brown color of lignin limits its use in transparent protective films.

The film, treated with red onion, showed promising features as it allowed more than 80 % of the sunlight at 650-1100 nanometer. The protection retained its good features throughout the long test period.

The durability and performance of materials was tested under artificial light for 1000 hours, which corresponds to about a year of sunlight in the open air in the Central European climate.

“Our results speak for long-term testing of materials, as the UV protection power and light transmission of all bio-based protective membranes changed in some way over time. For example, the membranes treated with iron ions passed through well at the beginning of testing, but as the material aged, the light permeability weakened,” Nizamov says in the release.

The protective membranes were tested with dye-sensitive solar cells because they are particularly susceptible to wear caused by UV radiation.

“However, the membranes we tested are also suitable for UV protection of other solar cells such as perovskite and organic cells.”